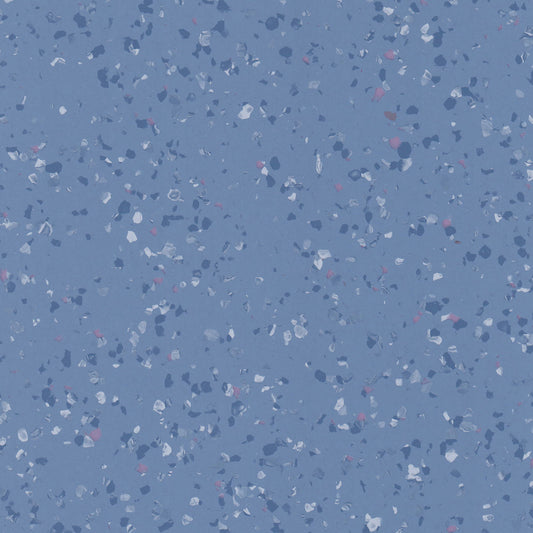

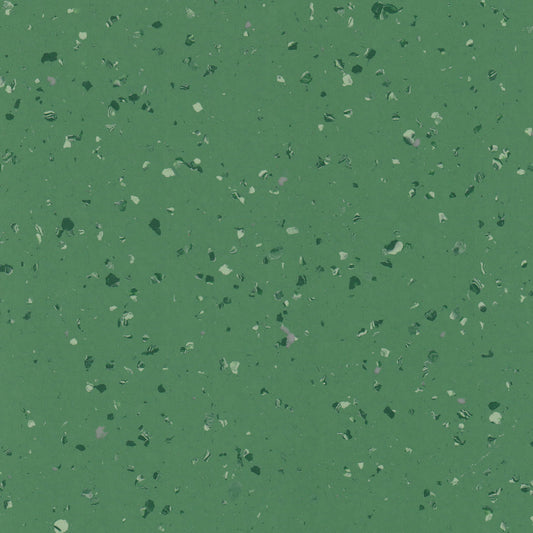

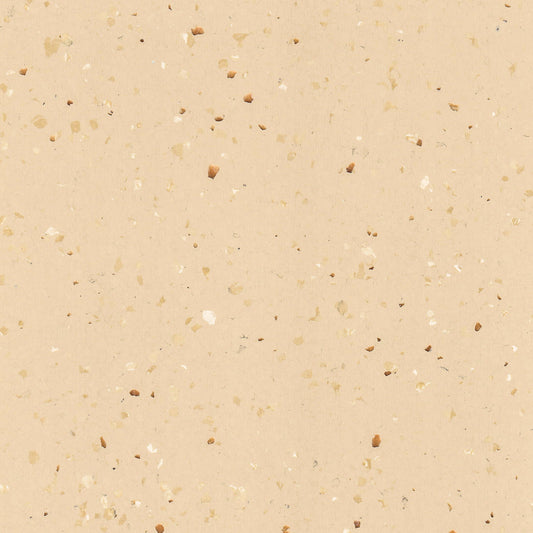

Electrostatic discharge (ESD) is a phenomenon that occurs when a static charge builds up on the surface of an object and is suddenly released. In many industries, ESD can pose significant risks, especially in environments where sensitive electronic components are handled. This is where ESD flooring comes into play.

What Is ESD Flooring:

ESD flooring is designed to control static electricity by grounding personnel and equipment, thereby preventing the buildup of electrostatic charges. This type of flooring is commonly used in environments such as electronics manufacturing facilities, data centers, laboratories, and clean rooms where even a small static discharge can cause irreversible damage to sensitive components.

The Science Behind ESD Flooring:

At its core, ESD flooring works by providing a conductive pathway for electrical charges to dissipate safely to the ground. The flooring is made from materials that have a controlled resistance to electricity, allowing static charges to flow through it without accumulating. There are three main types of ESD flooring based on their electrical resistance:

-

Conductive Flooring: This type of flooring has a low electrical resistance, typically between 2.5 x 10^4 and 1.0 x 10^6 ohms. Conductive flooring allows charges to flow easily to the ground, making it ideal for environments with high-risk static generation.

-

Static Dissipative Flooring: With a slightly higher resistance range (1.0 x 10^6 to 1.0 x 10^9 ohms), static dissipative flooring offers a controlled pathway for static charges to dissipate. It is commonly used in areas where both static discharge protection and personnel safety are concerns.

-

Anti-static Flooring: This type of flooring has the highest resistance range and is designed to reduce the generation of static charges rather than dissipate existing ones. It is often used in areas where static is not a critical concern but needs to be minimized, such as in office environments.

How ESD Flooring is Installed:

The effectiveness of ESD flooring depends heavily on proper installation. ESD flooring is usually installed with conductive adhesives that help to maintain the flooring's conductive properties. In some cases, grounding strips are placed beneath the flooring and connected to a grounding point in the building. These strips ensure that any static charges are effectively grounded, providing a reliable path for the electricity to travel.

It's also essential to pair ESD flooring with other ESD control measures, such as grounding wrist straps, ESD-safe shoes, and ESD workstations, to create a comprehensive static control environment.

Applications of ESD Flooring:

ESD flooring is used in a wide range of industries and environments where static control is critical. Some common applications include:

-

Electronics Manufacturing: In these environments, even a small static discharge can destroy delicate components or cause latent defects that lead to product failure. ESD flooring helps protect these components by preventing static buildup.

-

Healthcare and Laboratories: In medical environments, static electricity can interfere with sensitive equipment or pose a fire hazard in the presence of flammable substances. ESD flooring reduces these risks by controlling static buildup.

-

Data Centers: Data centers house sensitive servers and networking equipment that are highly susceptible to static discharge. ESD flooring in data centers ensures the protection of this vital equipment.

Conclusion:

ESD flooring is a critical component of static control in many industries. By providing a safe pathway for static electricity to dissipate, ESD flooring protects sensitive electronic components, enhances safety, and ensures the smooth operation of critical environments. When properly installed and maintained, ESD flooring is an effective solution for managing static electricity in any environment.

For more information on ESD flooring and its applications, visit our website or contact us today.